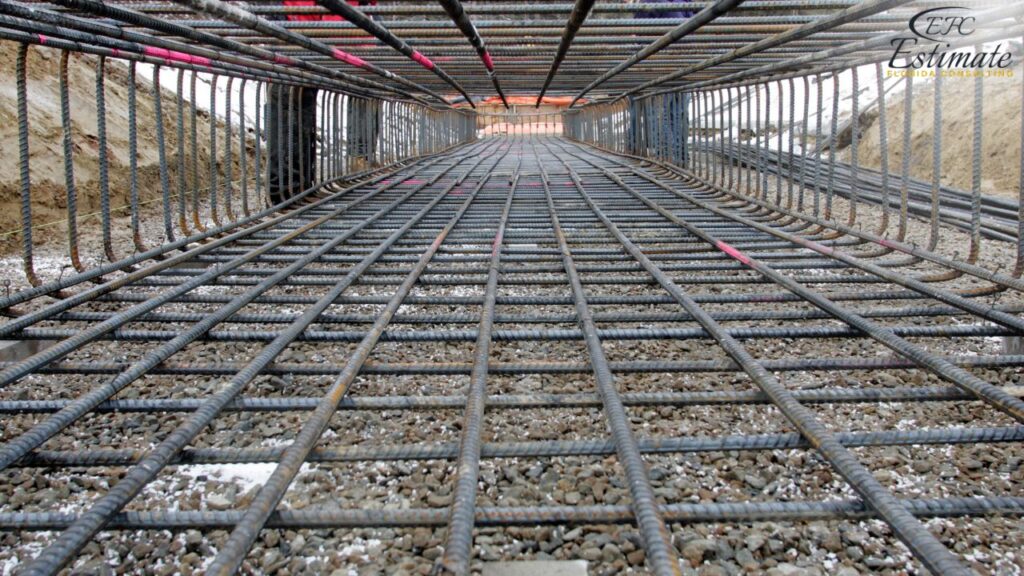

In the realm of large infrastructure projects, the choice of materials can significantly influence both the budget and the overall success of the endeavour. One of the most critical components in construction is rebar, or reinforcing bar, which plays a vital role in providing structural integrity to concrete. This article explores cost-effective rebar solutions that not only enhance the durability of large infrastructure projects but also optimise expenditure.

The Importance of Rebar in Infrastructure Projects

Rebar is essential in reinforcing concrete structures, which are inherently strong in compression but weak in tension. By incorporating reobar, engineers can ensure that structures can withstand various stresses and strains, extending their lifespan and safety. The significance of rebar cannot be overstated, particularly in large-scale projects such as bridges, highways, and commercial buildings.

Structural Integrity and Safety

In large infrastructure projects, safety is paramount. The use of high-quality rebar ensures that structures can endure natural forces such as earthquakes, floods, and heavy winds. A well-reinforced concrete structure can prevent catastrophic failures, protecting both the investment and the lives of individuals using the infrastructure. Additionally, the design and placement of rebar must be meticulously planned to accommodate the specific loads and environmental conditions a structure will face. This attention to detail not only enhances safety but also contributes to the overall resilience of the infrastructure, allowing it to perform reliably over time.

Cost Implications

While the initial cost of rebar may seem substantial, the long-term savings associated with reduced maintenance and increased durability can be significant. Investing in quality rebar can lead to fewer repairs and replacements over the lifespan of the structure, ultimately resulting in lower overall costs for the project. Furthermore, the choice of rebar material—whether it be epoxy-coated, stainless steel, or traditional carbon steel—can also influence both the upfront expenditure and the longevity of the structure. By selecting the most appropriate type of rebar for the given environmental conditions, engineers can further optimise the cost-effectiveness of the project, ensuring that it remains economically viable throughout its operational life. This strategic approach not only benefits the project stakeholders but also contributes to the sustainability of infrastructure development as a whole.

Factors Influencing Rebar Costs

Understanding the various factors that influence rebar costs is crucial for project managers and engineers. By being aware of these elements, stakeholders can make informed decisions that lead to more cost-effective solutions.

Learn more on: Everything You Need to Know About Using Reobar in Concrete

Material Prices

The price of raw materials used in the production of rebar can fluctuate due to market conditions. Factors such as demand, availability, and geopolitical issues can all impact pricing. Keeping abreast of these trends can help project managers secure better deals and plan budgets more effectively. Additionally, the quality of the raw materials can also affect the final price; higher-grade steel may command a premium but can offer improved durability and performance, which may ultimately save costs in maintenance and repairs over the lifespan of a structure.

Manufacturing and Transportation

Manufacturing processes and transportation logistics also play a significant role in the overall cost of rebar. Selecting local suppliers can reduce transportation costs and lead to quicker delivery times, which can be critical in large-scale projects where time is of the essence. Furthermore, understanding the manufacturing processes can help in choosing the most cost-effective options without compromising quality. Innovations in manufacturing, such as the use of recycled materials or more efficient production techniques, can also influence costs positively. Moreover, the choice of transportation—whether by road, rail, or sea—can significantly impact the final price, especially if the project is located in a remote area where logistics may be more complex and costly. Find more about materials on https://matse.illinois.edu/research/materials-medicine

Innovative Rebar Solutions

With advancements in technology and materials science, numerous innovative rebar solutions have emerged. These alternatives not only promise cost savings but also enhance the performance of concrete structures.

Steel Alternatives

While traditional steel rebar is widely used, alternative materials such as fibre-reinforced polymer (FRP) rebar are gaining popularity. FRP rebar is lightweight, resistant to corrosion, and offers similar tensile strength to steel. Although the initial cost may be higher, the long-term benefits, including reduced maintenance and extended service life, make it a cost-effective option for many projects. Furthermore, FRP rebar’s non-magnetic properties make it particularly advantageous in applications where electromagnetic interference must be minimised, such as in certain medical and scientific facilities. As the construction industry continues to evolve, the adoption of such innovative materials is likely to increase, paving the way for more resilient and sustainable infrastructure.

Recycled Rebar

Utilising recycled steel for rebar production is another cost-effective solution. This not only reduces the environmental impact of construction projects but can also lower material costs. Many suppliers now offer recycled rebar that meets industry standards, making it an attractive option for eco-conscious projects. The recycling process itself has become more efficient, with advanced technologies allowing for the extraction of high-quality steel from scrap materials. This not only conserves natural resources but also significantly reduces the carbon footprint associated with steel production. Additionally, as the demand for sustainable building practices grows, the use of recycled rebar is increasingly seen as a benchmark for responsible construction, encouraging more companies to adopt environmentally friendly practices in their operations.

Optimising Rebar Usage

Efficient use of rebar can lead to significant cost savings in large infrastructure projects. By employing strategic planning and innovative techniques, project managers can optimise rebar usage without compromising structural integrity.

Design Efficiency

Engaging in thorough design planning is essential for optimising rebar usage. Advanced software and modelling techniques can help engineers identify the most efficient configurations for rebar placement, ensuring that materials are used effectively. This not only reduces waste but also minimises costs associated with excess materials.

Prefabrication Techniques

Prefabrication of rebar assemblies can further enhance efficiency. By fabricating rebar components off-site, projects can reduce on-site labour costs and time. Prefabricated rebar can be delivered ready to install, streamlining the construction process and reducing the likelihood of errors that may lead to additional costs.

Case Studies of Cost-effective Rebar Solutions

Examining real-world examples of successful infrastructure projects can provide valuable insights into the implementation of cost-effective rebar solutions. These case studies highlight the practical application of innovative techniques and materials.

Bridge Construction in Queensland

A recent bridge construction project in Queensland utilised recycled rebar, resulting in significant cost savings. By sourcing materials locally and opting for recycled steel, the project not only reduced expenses but also contributed to sustainability goals. The bridge has since demonstrated exceptional durability, proving the effectiveness of this approach.

Highway Expansion Project

In a major highway expansion project, engineers employed advanced modelling software to optimise rebar placement. This strategic approach reduced the overall quantity of rebar required, leading to substantial cost savings. The project was completed ahead of schedule, showcasing the benefits of efficient planning and execution.

Future Trends in Rebar Solutions

The construction industry is continually evolving, and staying ahead of trends is essential for maximising cost-effectiveness. Emerging technologies and materials are set to reshape the landscape of rebar solutions in the coming years.

Smart Rebar Technologies

Smart rebar technologies, which incorporate sensors and monitoring capabilities, are gaining traction. These innovations allow for real-time monitoring of structural integrity, enabling proactive maintenance and reducing long-term costs. As these technologies become more accessible, they are likely to revolutionise the way rebar is utilised in infrastructure projects. To learn more about integrity click here.

3D Printing and Custom Solutions

3D printing is another exciting trend that holds promise for the future of rebar solutions. Customised rebar shapes and configurations can be produced with precision, reducing waste and optimising material usage. As 3D printing technology advances, it may become a standard practice in large infrastructure projects, further driving down costs.

Conclusion

In conclusion, the selection and application of rebar in large infrastructure projects can significantly impact both costs and structural integrity. By exploring innovative solutions, optimising usage, and staying informed about industry trends, project managers can achieve cost-effective outcomes without compromising quality. As the construction industry continues to evolve, embracing these advancements will be key to delivering successful infrastructure projects that stand the test of time.